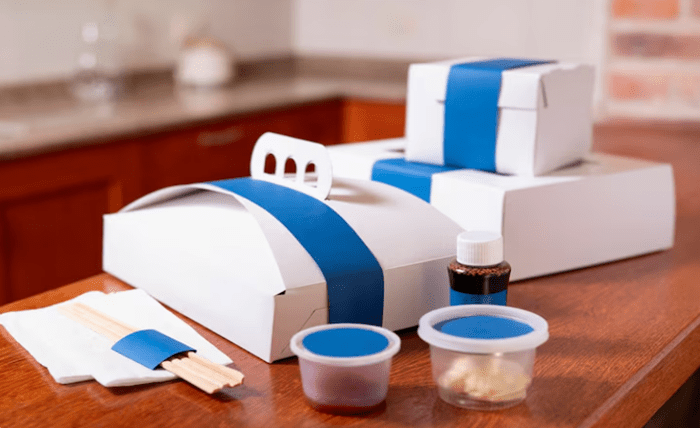

Premade custom foam designs are revolutionizing packaging by offering pre-engineered solutions that balance convenience, protection, and customization for businesses and individuals alike. These ready-to-use foam inserts, tailored for specific equipment or case types, provide professional-grade protection without the time-intensive process of designing from scratch. As industries from photography to aerospace seek efficient packaging solutions, premade designs deliver a practical and cost-effective way to safeguard valuable items during transit and storage.

The Appeal of Premade Foam Designs

The demand for efficient packaging has grown alongside global shipping and e-commerce, with businesses needing reliable solutions to protect products like cameras, firearms, and medical devices. Premade custom foam designs, as offered by companies like MyCaseBuilder and Cobra Foam Inserts, address this need by providing pre-designed inserts for popular case models, such as Pelican or SKB cases. These designs are crafted using advanced techniques like CNC cutting and waterjet technology, ensuring a snug fit for specific gear, as highlighted in TechBullion’s coverage of their scalability and reliability.

Unlike fully custom inserts, which require detailed design processes, premade designs are ready-to-use or slightly customizable, saving time and reducing costs. For example, MyCaseBuilder’s online editor allows users to tweak templates by adding finger notches or adjusting cutouts, offering a hybrid approach that combines speed with flexibility. This makes premade designs ideal for small businesses, hobbyists, and industries needing quick, high-quality packaging solutions without extensive lead times.

Applications Across Industries

The versatility of premade custom foam designs makes them invaluable across diverse sectors. In photography, inserts designed for camera gear protect lenses and bodies during travel, ensuring delicate equipment arrives undamaged. The firearms industry relies on premade designs for cases like the Pelican 1550, providing secure storage for pistols and rifles, as noted in TechBullion’s examples. Aerospace and medical sectors use these designs for standardized equipment, ensuring consistent protection during transport.

Hobbyists, such as watch collectors or drone enthusiasts, benefit from premade designs tailored to their needs, offering professional-grade organization without custom engineering costs. These designs are also scalable, supporting bulk orders for businesses like trade show exhibitors or sales teams, who use them to enhance product presentations. The ability to incorporate branding, such as laser-etched logos, further elevates their appeal, creating a polished, professional look.

Manufacturing Process and Quality Control

The production of premade custom foam designs involves precision engineering to ensure reliability. Companies like Cobra Foam Inserts use CNC cutting and waterjet technology to create accurate, smooth-edged inserts, as described in web sources. The process begins with designing templates for common equipment, such as cameras or tools, using computer-aided design (CAD) software. These templates are then cut from materials like polyethylene (PE) foam, known for its shock absorption, or polyurethane (PU) foam for softer cushioning.

Quality control is rigorous, with manufacturers conducting fit testing to ensure inserts match equipment dimensions precisely. Drop and impact testing simulate real-world shipping conditions, while surface inspections check for flaws like rough edges, as outlined in Royal Case’s manufacturing guide. These measures ensure premade designs meet industry standards, providing consistent protection and durability, with a lifespan that can exceed a decade under proper storage conditions.

Benefits for Businesses and Consumers

The adoption of premade custom foam designs offers transformative benefits. They reduce lead times significantly, with providers like MyCaseBuilder delivering solutions in days rather than weeks, compared to fully custom inserts. Cost efficiency is another advantage, as premade designs eliminate the need for extensive design phases, making them accessible for small businesses and individuals. Protection is enhanced, with foam inserts reducing damage risks by absorbing shocks and vibrations, as noted in Plexform’s analysis of their superior protective capabilities.

Branding opportunities are a key draw, with options like color-coded foam layers or engraved logos enhancing product presentation. This is particularly valuable for sales teams showcasing high-end products at trade shows, where professional packaging can influence client perceptions. Scalability ensures these designs meet both small and large-scale needs, supporting industries like automotive, where replacement parts require precise protection during transit.

Challenges and Solutions

Despite their advantages, premade custom foam designs have limitations. They may not perfectly fit unique or unconventional equipment, requiring users to opt for fully custom solutions in some cases. Budget-conscious buyers may find premade designs pricier than generic foam padding, as highlighted in TechBullion’s cost analysis. Manufacturers address this by offering competitive pricing for bulk orders and simpler designs, as seen with Custom Foam Parts.

Environmental concerns are another challenge, as traditional foam materials contribute to plastic waste. Companies like Disc Makers, though primarily focused on media, offer insights into sustainable packaging trends, with premade foam providers adopting recycled or biodegradable materials to align with consumer demand. Integration with existing cases is simplified through precise measurements, ensuring compatibility with standard case models.

Future Trends and Innovations

The future of premade custom foam designs is shaped by technological and environmental advancements. Automation in manufacturing, such as high-speed CNC cutting, reduces costs and improves precision, making designs more accessible. Sustainable materials, like biodegradable PE foam, are gaining traction, addressing environmental concerns. Blockchain could enhance supply chain transparency, ensuring ethical sourcing of materials, while 3D printing may enable rapid prototyping of premade designs for niche applications.

Consumer demand for customization is driving innovations, with online editors like MyCaseBuilder’s allowing real-time design tweaks. These trends suggest premade designs will remain a vital packaging solution, balancing efficiency with personalization in an eco-conscious market.

Real-World Impact

A photography studio using Cobra Foam Inserts’ premade designs reported zero equipment damage during international shoots, saving thousands in replacement costs. A firearms retailer leveraging MyCaseBuilder’s designs enhanced customer satisfaction by offering branded, secure storage solutions. These examples underscore the practical value of premade foam designs in diverse applications.

Conclusion: Streamlining Protection with Premade Designs

Premade custom foam designs offer a compelling blend of convenience, protection, and customization, making them a go-to solution for industries and individuals needing efficient packaging. As technology and sustainability evolve, these designs will continue to meet diverse needs, ensuring products arrive safely and stylishly in an increasingly demanding market.